-

1

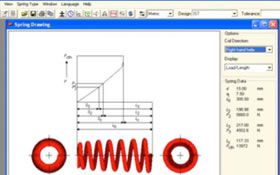

Design

All spring designs are designed on an advance cad program. Design requirements include “Maximum durability”, “Lowest weight” , “Maximum travel”, “Tapered wire” and “Progressive pitch” designs. Sized in 0.25mm increments and 8mm material to 24mm material are used.

-

2

Material

Only X5K material is used. X5K is a new generation High Strength Spring Steel which with-stands higher operating stresses and has superior resistance to sag, improved toughness and improved corrosion fatigue properties.

-

3

Peeling & Tapering

Bar peeling and Tapering production line. Peels 1mm from the surface of the material removing any surface defects. Tapers up to 7mm from “parent” material. Peels diameter to any size, down from 24mm.

-

4

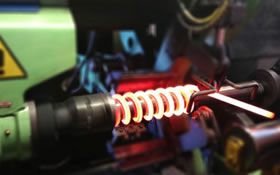

Heating

Gas furnaces are used for their extremely clean and efficient heating properties. Coils are heated to around 1000 degrees Celsius before being rolled.

-

5

Coiling

Computer controlled coilers are used to roll the coils whilst the bar is still over 950 degrees Celsius. Coilers have variable pitch speeds to manufacture the progressive pitch coils. Pitch has a tolerance of less than 1mm.

-

6

Hardening

Once the coil is rolled it is then placed into the Quenching oil whilst still at 850 degrees Celsius and hardened to 62 HRC (Rockwell hardness)

-

7

Tempering

After the Hardening process the coil is then placed into the Tempering oven and heated back up to 400 degrees Celsius . Coil will be now tempered to a 54 HRC. This is done via a computer controlled and monitored gas furnace.

-

8

Spring end grinding

Once the coil is tempered and if the coil design requires the coil to be ground square, then the coils are fitted into one of 5 Computer controlled wet grinders.

-

9

Shot peening

The coil is now placed into our Conveyor fed shot peener and rotated for 100% coverage. This gives the coil a high intensity finish to ensure maximum fatigue life and an optimal surface for the powder coat to be applied to.

-

10

Pre-treatment

Coil is now dipped with a phosphate coating for maximum corrosion protection.

-

11

Powder coating

Coils are now hung and sprayed with an Epoxy powder coat to achieve the most durable finish and offering maximum presentation.

-

12

Ink printing

Once powder coated the coil is then Ink Jet printed with durable, fast curing ink with both part number and batch number for traceability.

-

13

Stock holding

King Springs stock over 60,000 coils (over 1500 part numbers) ready for instant dispatch.

-

14

Sales and service

King Springs have an experience and dedicated sales and technical team ready to take your call.